MFB lamination line. productivity – 10 000 m3 / year

|

Name

|

Number

|

Quantity

|

|

1. Raw materials preparation

|

|

|

|

1. Raw materials feeding belt conveyor

|

Gz01

|

1

|

|

2. Drum shaving machine

|

BX218

|

1

|

|

3. Chip wind system

|

GZ07

|

1

|

|

2. Fiber preparation

|

|

|

|

4. Belt conveyor

|

GZ08

|

1

|

|

5. Electric iron remover

|

GZ09

|

1

|

|

6. Bunker for thermal abrasive material (18m3)

|

GZ10

|

1

|

|

7. Thermal attritor

|

JM9F

|

1

|

|

8. Dusting machine

|

|

1

|

|

9. Raw materials feeding pipe

|

GZ12

|

1

|

|

10. Paraffin spray system

|

GZ15

|

1

|

|

11. Mastic spray system

|

GZ18

|

1

|

|

12.Wind pipe of fiber dryer

|

|

1

|

|

13. Spark detector and fire-fighting device

|

GZ20

|

1

|

|

14. Dry raw materials bunker

|

GZ24

|

2

|

|

3. Stacking of hot press

|

|

|

|

15. Power transportation stacking system

|

GZ25

|

2

|

|

16.Former of fiber stacking

|

GZ26

|

1

|

|

17Former transportation system.

|

GZ26

|

1

|

|

18. Fiber stack transportation system

|

GZ28

|

1

|

|

19. №1 Transportation system of pure air flow for stacking

|

GZ29

|

1

|

|

20. №2 Transportation system of pure air flow for stacking

|

GZ29

|

1

|

|

21. Electronic name of slab

|

GZ30

|

1

|

|

22. Forepress

|

GZ31

|

1

|

|

23. Synchronous transportation equipment

|

GZ32

|

1

|

|

24Cross cut saw

|

GZ33

|

1

|

|

25. Horizontal saw

|

GZ34

|

1

|

|

26. Slab sprayer

|

GZ35

|

1

|

|

27. Transportation system of pure air flow for waste collection by slab saw

|

GZ36

|

1

|

|

28.Transportation system of pure air flow for slab collection

|

GZ37

|

3

|

|

29. Accelerating conveyor

|

GZ38

|

1

|

|

30. Reserve conveyor

|

GZ41

|

1

|

|

31. Coveler plate packer

|

GZ43

|

1

|

|

32. Pressing machine

|

GZ45

|

1

|

|

33. Unloader

|

GZ46

|

1

|

|

34. Hydraulic system of the presser

|

GZ47

|

1

|

|

35. Producing conveyor

|

GZ50

|

1

|

|

36. Cooler

|

GZ51-53

|

1

|

|

4.Production

|

|

|

|

37. Pusher

|

|

1

|

|

38. Inclined drum conveyor

|

LJJ901.1

|

1

|

|

39. Vertical saw

|

LJJ901.2

|

1

|

|

40. Raw materials feeding conveyor for vertical saw

|

LJJ901.3

|

1

|

|

41. . Raw materials feeding conveyor for horizontal saw

|

LJJ901.4

|

1

|

|

42. Horizontal saw

|

LJJ901.5

|

1

|

|

43. Raw materials feeding conveyor for horizontal saw

|

LJJ901.6

|

1

|

|

44.Hyraulic elevator

|

TJ51A

|

1

|

|

45. Dust removal system of a saw

|

GZ62

|

1

|

|

46. Hydraulic lifting device

|

TJ51A

|

1

|

|

47. Inclined swaying conveyor

|

LIJ901.1

|

1

|

|

48. Inclined drum conveyor

|

BSG2713QE

|

1

|

|

49. Releasing conveyor

|

|

1

|

|

50. Hydraulic elevator

|

TJ51

|

1

|

|

51.

|

GZ62

|

1

|

|

5.Electronic control system

|

|

|

|

52. Electronic control equipment – chips preparation stage

|

GZ63

|

1

|

|

53. Electronic control equipment – fiber preparation stage

|

GZ64

|

1

|

|

54 Electronic control equipment –hot pressing for subsequent molding stage

|

GZ65

|

1

|

|

55. Electronic control equipment for cooling system

|

GZ66

|

1

|

|

56. Electronic control equipment – dust removal at sidewall cutting

|

GZ67

|

1

|

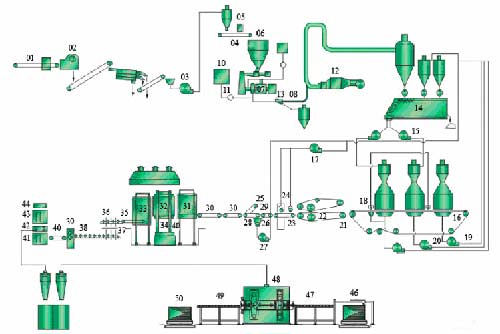

Drawing of production line for medium density Fiber boards (30 000 m3 year)

Conventions

|

1. Raw materials feeding belt conveyor

2. Drum shaving machine

3. Chip wind system

4. Belt conveyor

5. Electric iron remover

6. Bunker for thermal abrasive material (18m3)

7. Thermal attritor

8. Dusting machine

9. Raw materials feeding pipe

10. Paraffin spray system

11. Mastic spray system

12.Wind pipe of fiber dryer

13. Spark detector and fire-fighting device

14. Dry raw materials bunker

15. Power transportation stacking system

16.Former of fiber stacking

17Former transportation system.

18. Fiber stack transportation system

19. №1 Transportation system of pure air flow for stacking

20. №2 Transportation system of pure air flow for stacking

21. Electronic name of slab

22. Forepress

23. Synchronous transportation equipment

24Cross cut saw

25. Horizontal saw

26. Slab sprayer

|

27. Transportation system of pure air flow for waste collection by slab saw

28.Transportation system of pure air flow for slab collection

29. Accelerating conveyor

30. Reserve conveyor

31. Coveler plate packer

32. Pressing machine

33. Unloader

34. Hydraulic system of the presser

35. Producing conveyor

36. Cooler

37. Pusher

38. Inclined drum conveyor

39. Vertical saw

40. Raw materials feeding conveyor for vertical saw

41. . Raw materials feeding conveyor for horizontal saw

42. Horizontal saw

43. Raw materials feeding conveyor for horizontal saw

44.Hyraulic elevator

45. Dust removal system of a saw

46. Hydraulic lifting device

47. Inclined swaying conveyor

48. Inclined drum conveyor

49. Releasing conveyor

50. Hydraulic elevator

|

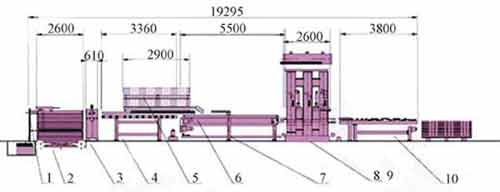

3. MFB PRODUCTION LINE, 50 000 M3/YEAR

|

Name

|

Number

|

Units .

|

|

1. Raw materials preparation

|

|

|

|

01. Raw materials feeding belt conveyor

|

GZ01

|

1

|

|

02. Drum shaving machine

|

BX218

|

1

|

|

03. Belt conveyor

|

GZ08

|

1

|

|

04. Magnetic iron remover

|

GZ07

|

1

|

|

05.Cup elevator

|

GZ09

|

1

|

|

06. Belt conveyor

|

GZ10

|

1

|

|

07. Bunker for thermal abrasive material

|

|

1

|

|

08.Belt conveyor

|

|

1

|

|

2. Fiber preparation

|

|

|

|

9. Thermal attritor

|

BM1111-15

|

1

|

|

10. Raw materials feeding pipe

|

GZ12

|

1

|

|

11. Paraffin spraying device

|

GZ16

|

1

|

|

12. Glue storage

|

GZ18

|

1

|

|

13. Glue spraying measuring device

|

GZ20

|

1

|

|

14.Air flow fiber dryer

|

GZ24

|

1

|

|

15. Dry materials storage bunker

|

GZ25

|

2

|

|

3. Hydraulic molding

|

|

|

|

16. Stacking conveyor

|

GZ26

|

1

|

|

17. Stacker

|

GZ28

|

1

|

|

18. Cut fiber force conveyor

|

GZ29

|

3

|

|

19. Dust catching vacuum conveyor

|

GZ30

|

1

|

|

20. Slab

|

GZ31

|

1

|

|

21. Forepress

|

GZ32

|

1

|

|

22. Synchronous conveyor

|

GZ33

|

1

|

|

23. Sidewall cutter

|

GZ34

|

1

|

|

24. Horizontal saw

|

GZ35

|

1

|

|

25. Bunker

|

GZ36

|

1

|

|

26. Saw, cleaner, power fiber conveyor

|

GZ37

|

1

|

|

27. Return force system

|

GZ38

|

|

|

28. Accelerating conveyor

|

GZ41

|

1

|

|

29. Reserve conveyor №1

|

GZ42

|

1

|

|

30. №2 reserve conveyor, №3 reserve conveyor

|

GZ42

|

1

|

|

31. Uncoveler sheet conveyor

|

GZ43

|

1

|

|

32.Presser

|

GZ45

|

1

|

|

33. Unloader

|

GZ46

|

1

|

|

34. Presser’s sale system

|

GZ47

|

1

|

|

35. Releasing conveyor

|

GZ50

|

1

|

|

36. Cooling roll conveyor

|

GZ51

|

1

|

|

37. Roll cooler

|

GZ52

|

1

|

|

38. Cooling release conveyor

|

GZ53

|

1

|

|

39. Stowing hydraulic elevator

|

GZ55

|

1

|

|

40.Hydraulic elevator

|

GZ57

|

1

|

|

41. Vertical and horizontal sidewall cutter

|

GZ54(JJJ901)

|

1

|

|

42. Inclined conveyor

|

GZ58

|

1

|

|

43. Polishing machine

|

BSG2713

|

1

|

|

44. Releasing conveyor

|

GZ60

|

1

|

|

45. Hydraulic elevator

|

GZ61

|

1

|

|

46. Dust collecting system

|

GZ62

|

1

|

|

47. Electronic control equipment – chips preparation stage

|

GZ63A

|

1

|

|

48. Electronic control equipment – fiber preparation stage

|

GZ64A

|

1

|

|

49. Electronic control equipment – hot pressing for molding

|

GZ65A

|

1

|

|

50 Electronic control equipment for cooling system

|

GZ66A

|

1

|

|

51. Electronic control equipment – dust collecting during cutting the sidewalls

|

GZ67A

|

1

|